Home > Products > titanium Materials > Titanium Bipolar Electrolyser Plate for Fuel Cell

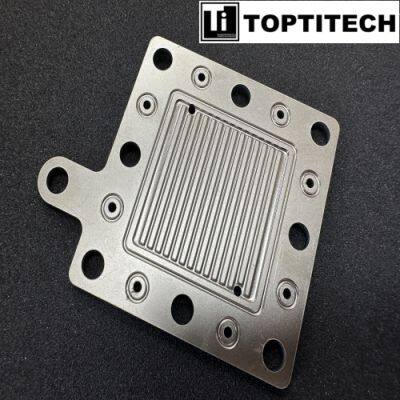

Titanium Bipolar Electrolyser Plate for Fuel Cell

- shanghai shenzhen tianjin

- T/T L/C D/P D/A Credit Card PayPal Cash Escrow Other

- 5 days

You May Like

-

Sintered Stainless Steel Medical Fine Diffuser Stone For Ozone Generator

-

Sintered Nickel Fiber Paper Nickel Felt For GDL

-

Sintered stainless steel filter cartridge cups

-

SS 316L Diffuser Stone For Ozone Generator Food Grade

-

316L sintered stainless steel hydrogen dissolving stone rod

-

Customized 0.5um Titanium Rod Filter Cartridge Special Interface

Product Details

| Brand Name | TopTiTech | Place of Origin | China | |

| Model Number | TA-04 | Application | Orthopedic implants, Ophthalmic implants, Dental Implants , Filling Materials | |

| Technique | plating,brushing | Grade | 1 | |

| Dimensions | customized | Powder Or Not | Not Powder | |

| Ti Content (%) | 99% |

Product Description

Product Introduction

Titanium bipolar electrolyser plate in electrolysis is a special electrode for electrolysis, usually made of pure titanium. In electrochemical processes, electrodes are usually divided into anodes and cathodes, each responsible for the flow of electrons and the flow of ions. A bipolar plate is an electrode that has both anodic and cathodic properties.

In electrolysis, titanium bipolar electrolyser plates are usually used in the fields of electroplating, electrolytic preparation and water treatment. They can withstand high voltage and high current density, but also have good corrosion resistance, which allows them to be used in harsh environments such as strong acid, strong alkali, high temperature and high pressure.

Parameters

Material: Gr1 titanium

Size: Customized according to the drawing

Application: Fuel cell

Features

1.Good electrical conductivity: Titanium bipolar plates have excellent electrical conductivity and can withstand high voltage and high current density, thus effectively promoting electrochemical reactions.

2.Good corrosion resistance: Titanium bipolar plates have good corrosion resistance and can be used in harsh environments such as strong acid, strong alkali, high temperature and high pressure, and are not easily corroded and worn.

3.Good mechanical properties: Titanium bipolar plates have high strength and rigidity, can withstand large forces and pressures, and are not easily deformed and broken.

4.Lightweight: Titanium bipolar plates have a lower density and are a lightweight material that can reduce the weight of the entire electrolytic cell and improve overall efficiency.

Methods of coatings for Ti bipolar plates

A number of methods are used to deposit coatings onto metallic bipolar plates. Processes include physical vapor deposition techniques such as electron beam evaporation, sputtering and glow discharge decomposition, chemical vapor deposition techniques, and liquid phase chemical techniques such as electroplating and electroless deposition, chemical anodizing/oxidation coatings and painting.

Processing

Titanium bipolar plates can be manufactured by CNC machining, hydraulic forming and stamping, and photochemical etching. The following is a brief description and comparison of these three methods:

CNC machining: CNC machining is a method of machining using computer-controlled cutting tools. When manufacturing titanium bipolar plates, CNC machine tools can be used to perform operations such as cutting and milling of titanium plates to produce the desired shape and size.

Hydroforming and stamping: Hydroforming and stamping are methods of shaping titanium plates using hydraulic pressure and dies. When manufacturing titanium bipolar plates, hydraulic presses or punching machines can be used to punch, form, and bend titanium plates.

Photochemical Etching: Photochemical etching is a method that uses light and chemical reactions to etch the surface of a material. When manufacturing titanium bipolar plates, photoresist technology can be used to cover the parts that need to be protected, and then irradiated and etched to produce the desired shape and size.

Package and Shipment

1. Sintered Filters are usually packed in cartons, wrapped in soft film, and fixed in a box filled with industrial foam cotton, and the outer baler is packed with plastic bags with no damage during transportation.

2. Wooden box export packaging can also be customized. The foam cotton can be filled and fixed, the external box is sealed, the bottom is specified, the whole packaging is processed, and the goods can be delivered to the customer's designated place without damage.

Contact Us

TEL: +8619992203758

FAX: 0917-3873009

Email:karrykang@bjygti.com

Company: TOPTITECH -- BAOJI YINGGAOCO., LTD

Website:/

ADD: No. 195, Gaoxin Avenue, High-tech Development Zone, Baoji City, Shaanxi, China

Contact Us

- TOPTITECH -- BAOJI YINGGAOCO.,LTD

- Contact nameKarry Chat Now

- Phone86-0917-3873009

- AddressHigh-tech Development Zone, Baoji, Shaanxi

Product Categories

| titanium filter | titanium Materials | Nickel products | stainless steel filter |

| brass filter | Filter |

New Products

-

0.6mm Sintered porous titanium sheet Porous Transport Layers for PEM electrolyzers

-

Sintered conical wire mesh filter strainer

-

0.22 Microns Sintered Stainless Steel Filter Ring

-

Versatile Monel Alloy Filter Plates Precision Filtration Needs

-

0.5microns sintered porous Ti plate for PEM electrode

-

Platinum Coated Porous Titanium Sheets Electrodes For PEM Water Electrolyzer

-

5um Porous Inconel 600 Metal Filter Element

-

Titanium micro porous flow channel plates

-

Nickel Fiber Felt For Electrolyzer GDL

-

4-layers Sintered Titanium Wire Mesh Filter Plate

-

Titanium electrodes with flow channels

-

Titanium Pipe for Exhaust and Downpipe

-

316L Tri Clamp Sanitary Filter for Milk Filtration

-

A 10 Micron Ultra-long Microporous Metal Titanium Plate

-

Titanium Plate With Flow Field For Electrolyzers

-

75um SS 304 Porous Wire Mesh Filter Cartridge

-

Porous Ti elements for temperature and humidity sensor protection cover

-

Porous Sintered Powder SS 316L Metal Plate Filter Semicircle

Popular Searches

- water treatment

- Titanium Alloy

- swimming pool

- titanium material

- titanium plate

- titanium tube

- titanium bar

- Water Treatment Plant

- titanium sheet

- titanium foil

- titanium bike frame

- electrolysis

- Titanium Electrode

- titanium mesh

- mmo anode

- Titanium Plate Anode

- titanium anode basket

- titanium mesh anode

- Titanium Sheet Anode

- gas generator

- power generator

- genset

- fuel tank

- fuel volume

- natural gas generator

- gas chp

- oil catch tank

- hydrogen equipment

- coal fired

- electrolysis cell

Recommended Products

- Manufacturers sell welding grade rutile sand

- 95% Rutile sand for welding electrodes

- 95% rutile sand, specifically used for welding electrodes.

- 95% rutile sand, specifically used for welding electrodes.

- 95% Rutile sand for welding electrodes

- High Quality Large central state-owned enterprises Storage Tank tower reactor

- 95% Rutile sand for welding electrodes

- 95% Rutile sand for welding electrodes

- High purity 95% rutile sand

- 95% Rutile sand for welding electrodes

- 95% Rutile sand for welding electrodes

- Petrochemical oil storage tank barrier explosion-proof material for gas stations, with a wide range of applications

Find Similar Products By Category

- Manufacturing & Processing Machinery > Chemical Equipment & Machinery > Pressure Vessel

Product Tags:

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

Karry

Hi there! Welcome to my shop. Let me know if you have any questions.

Karry

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile